In today’s oil and gas operations, reliability, efficiency, and safety are non‑negotiable. Every process stream, from amine systems to produced water depends on clean, consistent filtration to protect equipment, maintain uptime, and reduce operating costs. That’s where the XtreamPure® filtration system, engineered by Parker and supplied by Mountleigh, delivers unmatched performance.

Engineered for Demanding Oil & Gas Environments

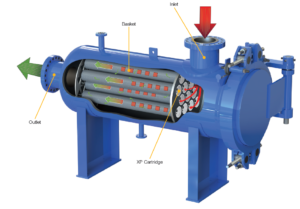

The XtreamPure® vessel, paired with XP‑L pleated high‑flow cartridges, is designed to outperform traditional filtration technologies. With a 6-inch diameter, multi‑layer W‑pleat media, and inside‑to‑outside flow direction, the XP‑L element captures contaminants internally, keeping the vessel clean and ensuring safer, faster change‑outs.

Key Advantages for Oil & Gas Operators

- High Flow Capacity Achieve up to 300 GPM per 60″ element at <2 psid in 1 cP fluids — ideal for high‑volume process streams.

- Chevron Seal Technology Parker’s patented chevron seal ensures absolute sealing, even when baskets or support plates are out of round. No bypass. No compromise.

- Longer On‑Stream Life The W‑pleat design maximizes dirt‑holding capacity, extending run times and reducing the number of cartridges required.

- Built for Harsh Chemistry Polypropylene construction and a wide pH range of 2–14 make XtreamPure® suitable for aggressive chemical environments.

- User friendly: Integrated handles make maintenance safer and faster, reducing downtime and labor costs.

Applications Across the Oil & Gas Value Chain

XtreamPure® filtration is trusted in:

- Produced water filtration (Deformable solids)

- High‑pH environments

- Amine systems

- Chemical and solvent filtration

- Process water treatment

- Reverse osmosis (RO) pre‑filtration

- General industrial liquid filtration

Whether you’re optimizing a water injection system, a gas plant, refinery, or chemical processing unit, XtreamPure® delivers the consistency and durability your operation demands.

Performance That Drives Savings

With 99.98% efficiency, fewer cartridges per vessel, and reduced maintenance requirements, XtreamPure® helps operators lower total cost of ownership while improving process reliability. For procurement teams, that means predictable performance and long‑term value. For operations teams, it means cleaner systems and fewer unplanned shutdowns

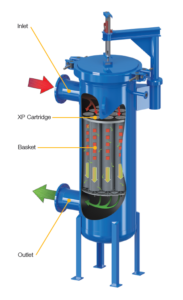

Vertical XtreamPure® Filtration: Engineered for Offshore Space Optimization

While the horizontal XtreamPure® vessel delivers exceptional performance for onshore and large‑footprint facilities, offshore environments demand a different approach. Space is limited, deck loading is tightly controlled, and equipment must integrate into compact modular skids. For these conditions, the vertical XtreamPure® (55VX) vessel provides a high‑capacity filtration solution without compromising footprint, accessibility, or safety.

Why the Vertical 55VX Vessel Excels Offshore

- High Flow Performance in a Compact Body

Depending on the model, the 55VX series supports:

- 200–17,000 GPM optimal flow rates

- 1 to 85 cartridges per vessel

- 10″ to 78″ vessel diameters

This ensures operators can scale filtration capacity without sacrificing space or accessibility.

- Safe and Efficient Maintenance

The vertical design maintains the same user‑friendly features as the horizontal vessel:

- No‑tool cartridge change‑outs

- Inside‑to‑outside flow for cleaner extraction

- Full‑end closure options to minimize confined‑space entry

- Cartridge baskets designed to withstand up to 50 psid

These features reduce maintenance time — a critical advantage in offshore environments where labor hours and safety exposure must be minimized.

- Engineered for Harsh Offshore Conditions

The 55VX vessels are available in carbon steel or stainless steel (304, 304L, 316, 316L), with optional coatings and NDT packages to meet offshore corrosion and inspection requirements. Design pressures range from 285 psig to 1480 psig, ensuring compatibility with high‑pressure process streams.

Partner With Mountleigh

As an authorized Parker distributor, Mountleigh supports both vertical and horizontal configurations and provides:

- Full Technical support – ensuring the right vessel and cartridge selection for your process conditions

- Fast delivery and reliable after‑sales service